We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Wire Manufacturers

The name "stainless steel" refers to an entire family of steel alloys made predominantly from iron ore high in chromium, not just one specific steel alloy. More specifically, this steel alloy contains at least 10.5% chromium at all times. It also contains smaller amounts of several other substances, including silicon, carbon, aluminum, molybdenum, and nickel. Each variety of stainless steel is unique because it is manufactured from a unique mixture of iron ore, chromium, and other components, each of which has strengths and weaknesses of its own.

Procedures for Creating Stainless Steel Wire

Casting and wire drawing are two of the most common wire-forming techniques used together to produce stainless steel wire. The alloyed steel material is heated before being cast or molded into stock shapes like ingots, billets, or rods as the initial step in wire forming. Then, the freshly produced stainless steel shape is narrowed to fit into a die by filing, rolling, swaging, or hammering. After that, the metal, referred to as a pre-form, is pulled through one or more dies, lengthening it overall while narrowing its diameter. The strand may only need to be pulled through one die if the target wire diameter is thick. After that, the strand will most likely be put through a series of ever-shrinking dies until it achieves the desired length and diameter, unless the desired wire diameter is thinner.

Although drawing is the most common technique for manufacturing stainless steel wire, other methods, such as stamping, extrusion, or rolling, may be used by producers instead. In addition, manufacturers can further specialize stainless steel wire by subjecting it to secondary processes like coating, painting, annealing, or galvanizing after the wire has been created. These treatments are intended to improve the wire's physical and aesthetic qualities, making it more durable and adaptable.

Stainless Steel Wire Design

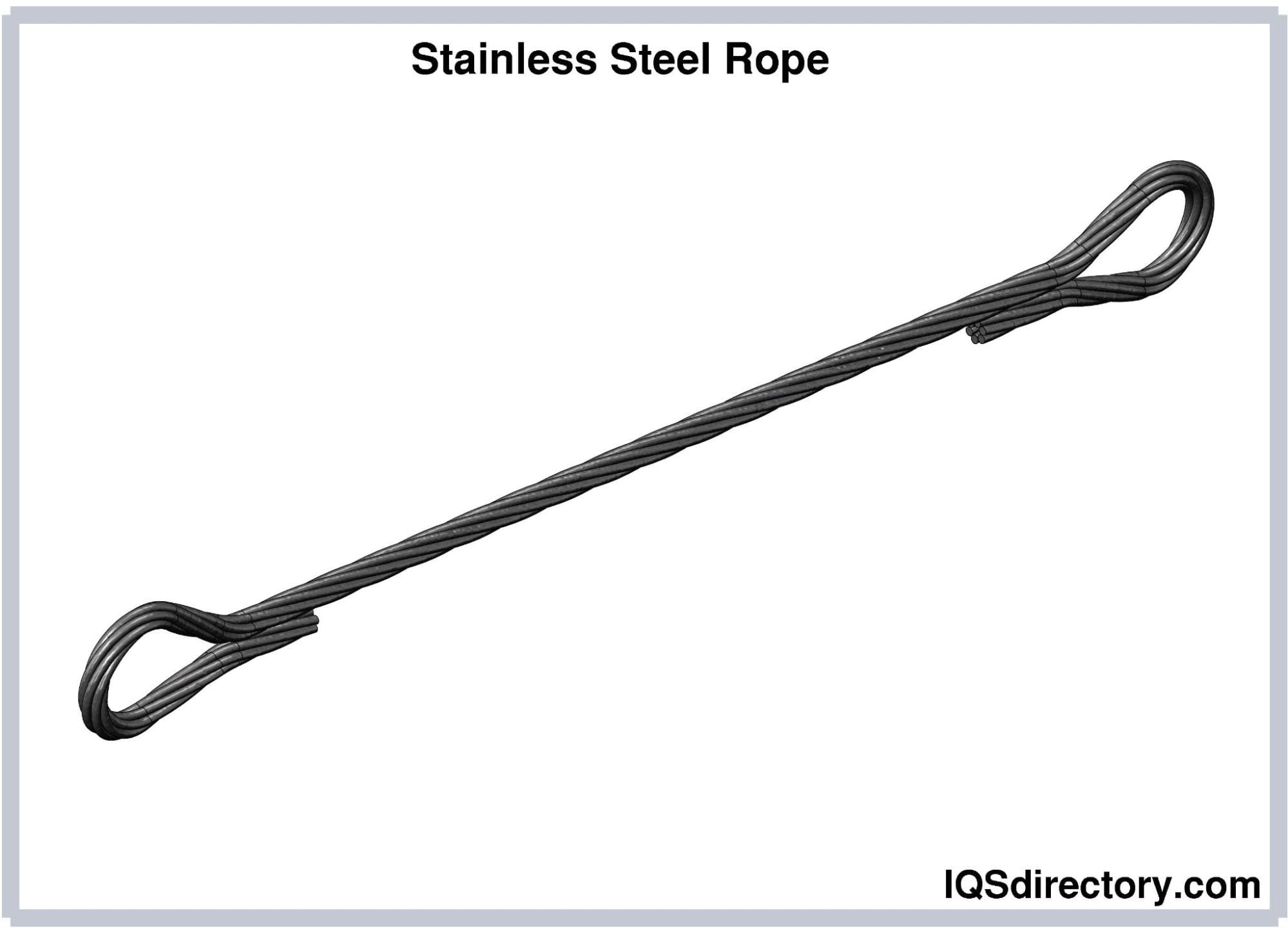

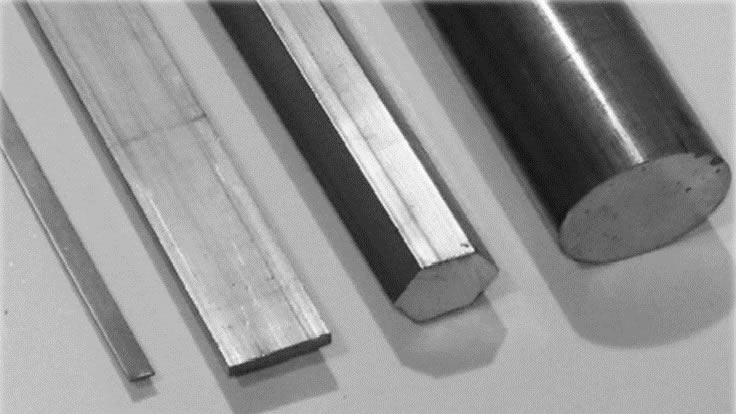

Although the diameter of stainless-steel wires varies, each filament's diameter is normally less than .375 inches. Additionally, although they can also be built with flat or other shaped cross sections, their cross sections are often spherical. In any case, stainless steel wire filaments can be used individually as thin wire or combined using braiding, twisting, weaving, or welding to produce additional new goods like shelving, baskets, or wire rope. Manufacturers will consider several factors when designing stainless steel or a stainless-steel wire product for a customer, including overall thickness or gauge, outer diameter, length and weight, and the stainless-steel grade that best matches the qualities they are looking for in the wire. For any stainless steel wire application, especially one involving a stainless steel rope, the proper composition, and characteristics must be used because the incorrect combination could result in subpar performance, a potentially expensive mechanical failure, or injury to human operators or bystanders. Because it provides options for both horizontal and vertical use, stainless steel wire rope is frequently employed. Railings made of horizontal ropes are very particular. Vertical wire ropes, on the other hand, provide a more appealing option that is excellent for architecture. Compared to horizontal ropes, these ropes offer a crisp, simple appearance.

Advantages of Stainless Steel

The chromium oxide protective layer surrounding stainless steel alloys gives them many amazing qualities, including strong corrosion resistance, heat resistance, wear resistance, impact resistance, good ductility, formability, hardness, weight-to-strength ratio, and hygiene. Because of these factors, stainless steel has a successful career as a multipurpose metal. A wire is one of the shapes that stainless steel is machined into most commonly.

Uses for Stainless Steel Wire

Stainless steel wire is widely used in various applications, including structural supports for the marine and construction industries and medical and dental tools and apparatus. Wire baskets, wire mesh, wire rope, stainless steel carts, and wire racks are just a few examples of the items created from or using stainless steel wire.

Things to Take Into Account When Buying Stainless Steel Wire

Consult a steel wire rope expert, such as a wire maker or a steel service center, for the finest guidance and outcomes. Start by looking through the list of seasoned steel wire experts from different manufacturers. Then, after identifying a manufacturer that would satisfy your requirements, get in touch with them by phone, email, faxing, or submit an online request for a price.

Choosing the Proper Stainless Steel Wire Manufacturer

To make sure you have the most productive outcome when purchasing stainless steel wires from a stainless steel wire manufacturer, it is important to compare at least 4 manufacturers using our stainless steel wire directory. Each stainless steel wire manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel wire business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel wire companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services