We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Bar Manufacturers

A stainless steel bar is made of iron and two or more chemical elements -often known as an alloy. A high chromium content can offer exceptional resistance to rust and staining. Stainless steel manufacturers offer several proprietary alloys in addition to the 57 standard stainless steel alloys. There countless uses for stainless steel alloys: building exteriors, roofs, bulk materials handling equipment, and vehicle parts.

Manufacturing of Stainless-Steel Bars

Stainless steel bars are made by melting Iron ore, chromium, silicon, nickel, and other raw elements together in an electric furnace. After 8 to 12 hours in intense heat, this mixture is cooled through quenching or air hardening. Depending on the amount of time spent cooling, the steel becomes either harder or softer. The stainless steel is descaled after cooling, which involves removing any accumulation using pickling or electrocleaning. Then the steel is cut using shearing, blanking, nibbling, or flame cutting to produce the final shape and size. Hot rolling, cold rolling, annealing, descaling, or other combinations of these procedures are used as further processing to provide certain finishes. Stainless steel bars are produced in grades 304 and 316.

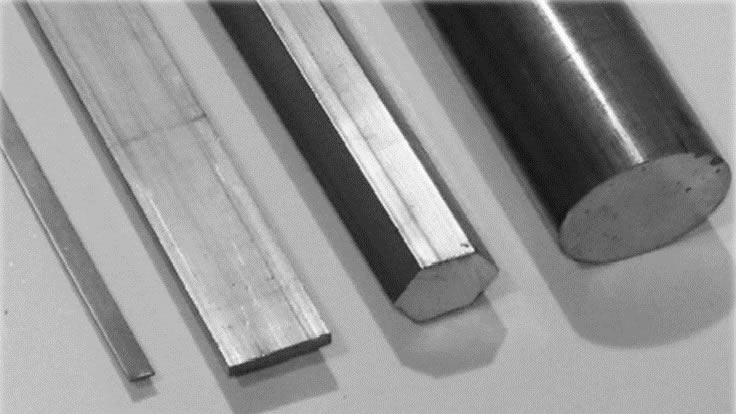

Shapes of Steel Bars

Flat Bars

Flat stainless-steel bars are hot rolled, thick, strong, and corrosion resistant. They are often sold as 316 or 304 stainless steel round bars. 316 is an upgraded variant of 304, because the 316 has more molybdenum and nickel, making 316 useful for severe environments. Molybdenum increases the steel's resistance to acetic acid vapors, seawater, and chloride-contaminated media. The steel maintains corrosion resistance in contaminated marine environments, and freezing temperatures. If you are welding steel for corrosive environments, search for manufacturers who offer the lower carbon type 316L.

The most adaptable and popular stainless steel is 304. Its chemical makeup, mechanical characteristics, weldability, and resistance to corrosion and oxidation make it the best all-around stainless steel at a competitive price. The 304 alloy responds well to cold treatment. If intergranular corrosion in the heat-affected zone is a possibility, it’s advised to use the 304L alloy.

Stainless Steel is used for a range of applications, from ornaments to dental braces.

Round Bars

Round stainless steel bars are easily cut, so they are often used to make machine parts and automotive components. It takes several steps to make round stainless steel bars. After being melted in the furnace, the steel is cast into semi-finished shapes called ‘billets’ or bars. The bars undergo a hot rolling process to be shaped as needed. Due to their corrosion resistance properties, stainless steel bars are fabulous for the production of automotive grills or construction fasteners.

Hexagonal Bars

Hexagonal bars are often used in construction industries as they are designed to carry weight.

Square Bars

Square bars are well-liked for their extreme resilience and power. Square bars are used as medium or large parts for industrial machinery. This form of steel is used widely in the manufacturing sector to make machinery, fasteners, and other equipment.

Choosing the Right Stainless Steel Bar Company

To make sure you have the most productive outcome when purchasing stainless steel bars from a stainless steel bar supplier, it is important to compare at least 5 companies using our stainless steel bar directory. Each stainless steel bar supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel bar business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel bar companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services