We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More 420 Stainless Steel Manufacturers

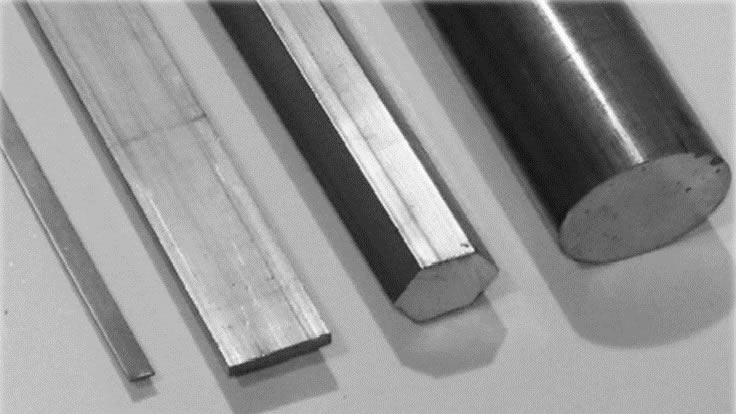

420 stainless steel is a high-carbon steel with a minimum 12% chromium content. When the 420 stainless steel is in it’s annealed form, it has high corrosion resistance qualities and good ductility. Heat treatment can harden grade 420 stainless steel.

Machining 402 Stainless Steel

The annealing processes involves heating 420 steels over 800°C, and then cooling them in an oven at a lower temperature. Then the steel is removed from the oven and air cooled.

Steels are preheated at 150 to 320°C and heated at 610 to 760°C during the welding procedure. When pieces are welded in the "as welded" condition, grade 309 filler rods are used to create ductile connections. 420 stainless steel is easier to work with in it’s annealed form.

However, grade 420's corrosion resistance characteristics often deteriorate in annealed conditions. Grade 420 steels are resistant to foods, mild acids, fresh water, alkalis, the air, and harsh conditions. 420 steel is used to make cutlery like carving and table knives. Although Grade 420 sheets of steel have considerable resistance to food-related corrosion, prolonged contact with unclean food ingredients can cause pitting corrosion.

Applications of Stainless Steel 420

Grade 420 stainless steel has a variety of applications, often used for cutting things because it is an incredibly hard metal. In the medical sector, it’s used for steel surgical tools like syringe valves. Because 420 steel is dense and corrosion resistant, it is ideal for crucial surgical operations and dental equipment. The steel is wear resistant enough for prolonged contact with human bone. Shear blades are also made of 420 steel because it is easy to sharpen.

Aside from cutting applications, stainless steel 420 works well for diesel engine pumps used in abrasive non-chlorinated contexts.

Choosing the Proper 420 Stainless Steel Supplier

To make sure you have the most positive outcome when purchasing 420 stainless steel from a 420 stainless steel supplier, it is important to compare at least 4 suppliers using our list of 316 stainless steel companies. Each 420 stainless steel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each 420 stainless steel business website using our patented website previewer to get an idea of what each 420 stainless steel company specializes in, and then use our simple RFQ form to contact multiple 420 stainless steel companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services