We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More 316 Stainless Steel Manufacturers

316 stainless steel has 3% molybdenum, 0.08% carbon, 14% nickel, and 18% chromium. Molybdenum increases the corrosion resistance of 316 stainless steel.

316 stainless steel is also called marine-grade stainless steel because it can resist chloride corrosion. Although it's not a recognized classification, "food-grade stainless steel" refers to 316 stainless steel. It is more chemically resistant to acidic and salt substances.

Applications for 316 Stainless Steel

316 stainless steel is used to construct exhaust manifolds, furnace components, heat exchangers, jet engine parts, pharmaceutical tools, photographic equipment, valves, pumps, chemical processing equipment, tanks, evaporators, and more. The industrial sector uses 316 steel when processing pulp, paper, textiles, and components exposed to maritime environments. In addition, 316 stainless steel is used in the food & beverage industries for brewing and dairy equipment.

Corrosion Resistance

316 stainless steel performs well in areas with high industrial pollution because it has high corrosion resistance. Water with large chlorine content may also cause pitting and crevice corrosion when in contact with 316 stainless steel. If care is taken to prevent crevice corrosion from occurring under sediments, precipitation, biofouling, and at designed-in fissures, 316 stainless steel can be used with seawater. Solutions with chloride ions may cause stress corrosion cracking on 316 stainless steel at temperatures greater than 60°C.

Fabrication

Grade 316 stainless steel is easy to fabricate using conventional sheet metal working techniques. Plasma cutting is common. It has an exceptional capacity for deep drawing. It is also relatively easier to forge. Grade 316 requires more power when machining. As a result, manufacturers may want to reduce the cutting speed, increase the food, and use heavier tooling and equipment.

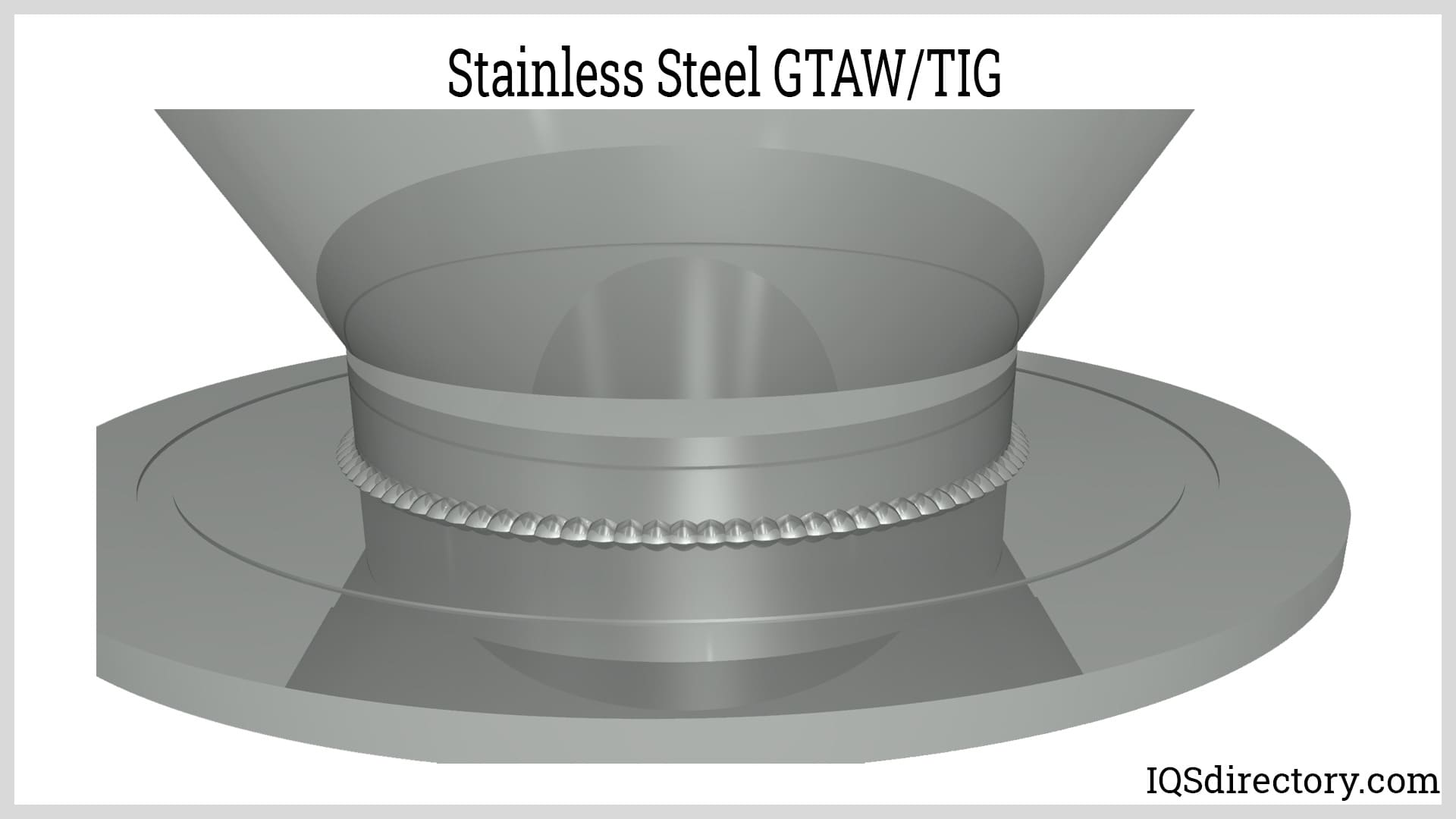

Heat Treatment and Weldability

To stop the precipitation of chromium carbides, solution annealing is carried out between 1065 and 1120°C, followed by fast cooling. Heat treatment will not make 316 harder. Due to the excellent ductility of 316, stress relief is rarely necessary.

Most fusion procedures (GTAW/TIG, GMAW/MIG/MAG, MMAW/stick, SAW) can easily weld grade 316 stainless steel without preheating or post-heating. However, to maintain corrosion resistance and strength, it is typically welded using filler metals of the same grade, such as 316 or 316L (or the variants that contain silicon). For welding grade 316 itself, these grades are pre-qualified weld metals according to AS1554.6:1994 standards.

Advantages of 316 Stainless Steel

The advantages of 316 stainless steel are numerous. It’s durable, with high corrosion and chlorine resistance. Molybdenum is a component of 316 stainless steel, which makes it superior to various chemical agents likely to cause corrosion on top of chromium and nickel. As a result, 316 stainless steel is a perfect metal for producing items related to surgery or food.

Stress corrosion cracking (SCC) resistance, pitting resistance, and creep resistance are all increased in the 316 stainless steel. Due to its strength, 316 stainless steel is easily fabricated without splitting. It also has good form and weld characteristics.

Choosing the Proper 316 Stainless Steel Supplier

To make sure you have the most positive outcome when purchasing 316 stainless steel from a 316 stainless steel supplier, it is important to compare at least 4 to 5 companies using our list of 316 stainless steel suppliers. Each 316 stainless steel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each 316 stainless steel business website using our patented website previewer to get an idea of what each 316 stainless steel company specializes in, and then use our simple RFQ form to contact multiple 316 stainless steel companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services