We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Manufacturers

Stainless steel, often referred to as chromium steel or corrosion-resistant steel, is an alloy of steel containing at least 10.5% chromium along with elements such as carbon, nickel, molybdenum, copper, manganese, titanium, nitrogen, silicon, and sulfur. In contrast to regular carbon steel, which has much lower chromium content, stainless steel is prized for its resilience and versatility.

Renowned for its exceptional strength and durability, stainless steel is scratch-resistant and remarkable at resisting rust, corrosion, and stains. It’s also known for its ease of cleaning and sterilization.

Originating from a base of iron and carbon, steel typically contains a maximum of 2.1% carbon. Stainless steel distinguishes itself by incorporating alloying elements that impart corrosion resistance. Belonging to a family of approximately 200 high-heat and corrosion-resistant steel alloys, stainless steel varies in carbon content from 0.03% to 1.2%.

Widely utilized across numerous industries, stainless steel experiences a robust 5% annual increase in demand. Its recyclability, derived from scrap sources, positions it as an environmentally friendly choice. Industries benefiting from stainless steel include:

- Food and catering

- Medical equipment

- Home appliances

- Chemicals and pharmaceuticals

- Offshore and shipbuilding

- Automotive manufacturing

- Energy and industrial sectors

- Architecture and construction

Stainless steel alloys derive their unique properties from a protective chromium oxide passivation layer. This layer shields against oxidation, a corrosive process fueled by oxygen reacting with iron molecules in the atmosphere. Even if scratched, the chromium oxide layer swiftly reforms, ensuring resilience against pores or cracks. This durability is pivotal in various applications.

Manufacturers and consumers alike favor stainless steel for its versatility across a spectrum of products and industries. From engineering and construction to everyday items like elevator doors and gutters, stainless steel finds extensive use, scaling up to monumental structures like skyscrapers.

History of Stainless Steel

Stainless steel emerged around the turn of the 20th century, though its roots extend back some 80 years before then. Pierre Berthier, a French metallurgist, sparked initial interest in 1821 by noting that iron alloyed with chromium resisted corrosion and proposing its use in cutlery. Unfortunately, early manufacturing lacked the expertise and tools to produce viable stainless steel alloys, resulting in brittle compositions.

In 1872, British metallurgists Clark and Woods achieved a breakthrough, creating a durable stainless steel alloy. Two decades later, Hans Goldschmidt’s thermite process facilitated the carbon-free production of chromium, enhancing stainless steel quality. Researchers swiftly refined stainless steel, with researchers like Frenchman Leon Guillet pioneering numerous varieties between 1904 and 1911.

In 1908, Friedrich Krupp Germaniawerft crafted the first stainless steel sailing yacht, marking a pivotal application. Meanwhile, in 1912, Harry Brearley serendipitously discovered martensitic stainless steel while searching for corrosion-resistant alloys for gun barrels. Around the same time, Krupp engineers Maurer and Strauss patented austenitic stainless steel as Nirosta.

Brearley’s collaboration with American Elmwood Haynes in forming the American Stainless Steel Corporation further popularized the material, leading to extensive use by 1929, with over 25,000 tons sold in the United States alone. Stainless steel soon became integral to military equipment during World War II and industrial machinery.

Today, stainless steel remains ubiquitous worldwide, with modern production focusing on sustainability and cost reduction.

Properties of Stainless Steel

Stainless steel boasts either high strength with low elongation or low strength with high elongation characteristics.

It performs exceptionally well at elevated temperatures due to superior resistance properties.

With the highest tensile strength among metals, stainless steel excels in various applications.

Its cryogenic properties are remarkable, making it indispensable in modern technologies.

Renowned for its exceptional ductility, stainless steel stands out in material sciences.

It exhibits extremely low electrical conductivity.

Thanks to its chromium content, stainless steel offers outstanding oxidation resistance.

Biologically inert, it’s ideal for kitchen appliances and cutlery.

Resistant to acids, bases, and organic compounds, stainless steel ensures durability.

Easily recyclable, workable, and effortlessly cleanable, stainless steel is a versatile material.

Stainless Steel Production Process

The process of stainless steel fabrication enables manufacturers to create a wide range of components and forms. Let’s explore each step of this process:

- Melting The journey begins with melting raw materials together in an electric furnace for 8-12 hours.

- Casting Once the molten material reaches a recrystallization temperature, it moves to the casting stage, where it takes on specific forms such as slabs, rods, blooms, billets, or tube rounds depending on its intended use.

- Hot Rolling The next step involves hot rolling, where the unfinished forms are shaped. Slabs are transformed into foil, strips, plates, and sheets, while blooms and billets are crafted into coils, bars, and wire.

- Heat Treatment and Air Hardening After shaping, the steel undergoes heat treatment and is air-cooled to achieve the desired hardness, which varies based on cooling time.

- Cleaning Following cooling, the steel is cleaned to remove any residues using methods such as electro-cleaning or pickling.

- Cutting In the final stage, the steel is precisely cut into the desired shapes and dimensions.

- Secondary Processing Additionally, the steel may undergo secondary processes like hot rolling, cold rolling, or annealing to achieve specific surface finishes, whether matte or shiny.

Stainless steel comes in over 150 different grades, each defined by its strength, alloy composition, temperature resistance, and intended use.

These grades fall into several principal types, each with distinct properties suited to various industries.

They can be categorized into four main groups based on their mechanical strength and resistance to corrosion:

- 200 Series: Combining manganese, chromium, and nickel, these non-magnetic alloys are highly resistant to attacks.

- 300 Series: Similar to the 200 Series but with higher chromium and nickel content, particularly the 316 type known for its exceptional corrosion resistance due to its high nickel ratio.

Grade 304 Stainless Steel : Also known as 18-8 stainless steel, contains 18-20% chromium and 8-10.5% nickel. Non-magnetic under annealing conditions, it can be weakly magnetic after cold treatments. It excels in corrosion resistance in mild atmospheres and freshwater but is susceptible to corrosion in the presence of halides. Widely used in food, electronics, medical equipment, and more.

Grade 310 Stainless Steel : Known as 18-10 stainless steel, it features a high chromium-nickel content with significant carbon. It exhibits high oxidation, creep, and heat resistance, making it prevalent in petrochemical and cryogenic applications.

- 400 Series: These alloys, with high chromium and low manganese, offer limited corrosion resistance. For instance, 420 stainless steel is part of this series.

Grade 430 Stainless Steel: Often referred to as 18-0 stainless steel, it contains 18% chromium and minimal nickel. Less expensive than the 300 series, it’s non-hardenable and resistant to oxidation and high temperatures. Used in applications like dishwasher linings, automotive trim, and industrial roofing.

- 600 Series: Known as precipitation hardening stainless steel, these alloys can resist chloride and water with proper heat treatment.

Each stainless steel grade serves specific industrial needs, from food processing to chemical applications, demonstrating varying levels of durability, resistance, and usability.

Types of Stainless Steel

Stainless steels are broadly categorized into three main types: austenitic, ferritic, and martensitic. Each blends varying proportions of nickel, carbon, and molybdenum.

Austenitic Stainless Steel:

Austenitic stainless steel comprises approximately 70% of all stainless steel production. It boasts the highest nickel content among the three types and is primarily found in the 200 and 300 series. Austenitic steels contain a minimum of 16% chromium, up to 0.15% carbon, and sufficient manganese or nickel to maintain their structure.

The most prevalent grade, 18/10, exhibits exceptional corrosion resistance, durability, and is favored for cryogenic applications due to its robustness under extreme temperatures. These steels are renowned for their weldability and find extensive use in industries requiring superior corrosion resistance, like cutlery manufacturing.

Ferritic Stainless Steel:

Ferritic stainless steels typically contain between 10.5% to 25% chromium and minimal nickel. Additional elements such as titanium, aluminum, or molybdenum may also be present. While offering good corrosion resistance, ferritic steels are economically advantageous compared to austenitic types, though their resistance to corrosion is slightly lower due to higher carbon and lower nickel content.

Martensitic Stainless Steel:

Martensitic stainless steel, characterized by higher carbon and molybdenum levels, sacrifices some corrosion resistance compared to austenitic and ferritic counterparts but excels in durability and machinability. With 12% to 14% chromium content, martensitic steels can be hardened for applications requiring tough, rust-resistant materials like cutlery and surgical instruments.

Duplex Stainless Steel:

A less common variant, duplex stainless steels combine approximately equal parts of austenite and ferrite, offering exceptional strength and resistance to various forms of corrosion including stress, crevice, and pitting. These steels are highly valued in applications prioritizing strength, such as pressure vessel construction.

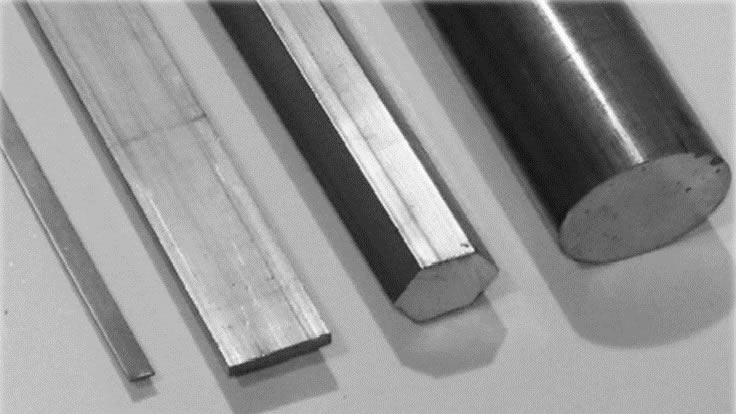

Products Produced from Stainless Steel

At a steel service center, you’ll discover a diverse array of stainless steel products and forms. Stainless steel suppliers offer an extensive selection, ranging from stainless steel foil, wire, strip, and bars to plate, coil, tube, seamless pipe, sheets, and rods.

These versatile shapes empower manufacturers to craft an array of items, from kitchen supplies and tableware to electronic appliances, flatware, laundry equipment, sinks, kegs, vats, silos, and large-scale kitchen machinery.

Benefits of Stainless Steel

Stainless steel offers numerous compelling reasons for its selection. Firstly, it stands out for its sustainability, being both recyclable and reusable. This not only benefits the environment but also contributes to substantial cost savings across all stakeholders. Additionally, stainless steel boasts remarkable versatility, available in over 150 standard variations tailored to diverse applications. Its inherent durability and strength further underscore its appeal. Unlike inferior metals, stainless steel resists corrosion, abrasion, and similar challenges without needing special coatings or finishes.

Why is High-Quality Steel the Preferred Choice?

Opting for high-quality steel ensures consistency in material properties. Whether for household projects or industrial endeavors, reliable steel is indispensable for engineering and safety.

The critical distinction is that low-quality steel fails to meet diverse requirements. Superior steel exemplifies durability, can withstand rigorous stresses, and achieves precise micrometer-level processing.

In contrast, lower-grade steel is prone to breakage and poses greater risks despite its commercial availability.

While the superiority of high-quality steel is undeniable, confirming its standards involves comprehensive testing for:

- Homogeneity

- Workability

- Hardening

- Tempering

- Resistance

- Elasticity

Familiarity with these technical aspects and adherence to updated ISO standards are crucial for understanding steel’s properties effectively.

Things to Consider Regarding Stainless Steel Manufacturers

When embarking on the search for a stainless steel contract manufacturer, several key considerations should guide your decision-making:

- Determine if the manufacturer offers the specific services you require.

- Ensure they can meet your exact specifications and quality standards.

- Assess their capability to deliver high-quality stainless steel products within your budget constraints.

- Verify their capacity to complete projects within your designated timeframe.

- Check for ISO certification or equivalent standards adherence to guarantee product quality and consistency.

- Confirm compliance with ASTM’s stringent safety and quality standards.

- Evaluate their proficiency in custom manufacturing.

Discover the expertise and capabilities of reliable and reputable stainless steel manufacturers featured throughout this page. Their detailed profiles will give you a clear understanding of their strengths and how they can meet your specific requirements.

What are the ISO Standards for Steel?

ISO standards from the International Organization for Standardization are pivotal in ensuring steel quality. ISO certification validates that manufacturing processes meet rigorous criteria. For instance, ISO categorizes metal materials, including steel under Group “P,” encompassing:

- Technical specifications

- General characteristics

- Supply conditions

- Testing and control

- Characterization methods

The widely recognized ISO 9001:2015 sets benchmarks for quality management systems. It mandates organizations to establish efficient quality processes, identify improvement opportunities, and implement necessary enhancements. Additionally, ISO standards such as ISO 377, ISO 404, ISO 10474, ISO 4948-1, and ISO 6929 provide specific guidelines for mechanical testing, technical delivery requirements, inspection documentation, and classification of steels based on chemical composition and product characteristics.

Stainless Steel Overseas Market

Production and trade span across the United States and international borders in the global stainless steel market. Many U.S. steel service centers not only cater to domestic clients but also serve foreign markets. Conversely, American businesses often import stainless steel from international fabricators. As of 2015, North America ranked third in steel production, trailing behind Asia, Oceania, and the EU.

Global competition has driven up domestic steel prices, prompting American customers to consider importing steel. Despite the potential cost savings of imports, there are compelling reasons to choose domestic suppliers. Communication with overseas companies can sometimes be challenging, leading to potential misunderstandings and delays in resolving issues with products that fail to meet specifications. Working with American suppliers also ensures adherence to U.S. safety and quality standards, providing greater confidence in product reliability.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services