We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Plate Manufacturers

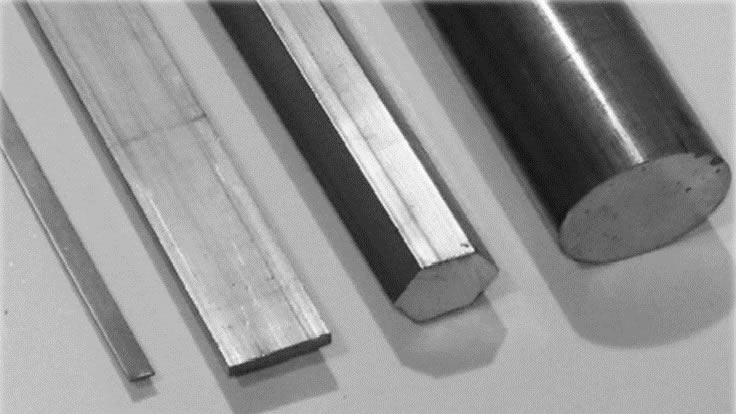

Many manufacturers consider slabs with a thickness between 0.25inches and 0.5inches to be plates. This common stock form is occasionally used as the end product, but more typically will undergo further manufacturing processes.

Stainless steel plates are ideal for a long list of industrial parts manufacturing processes such as welding, drilling, machining, shearing and forming. Building, construction, automotive, electronics, aerospace, marine, electronics, chemical processing, residential and many other industries commonly use stainless steel plates for components ranging from pipelines to protective plating to oil rigs.

Such applications favor stainless steel plate for more than its workability. The material is well known for its superior resistance to rust, wear and corrosion even in harsh environments. Additional qualities of stainless steel plate will vary depending upon the specific grade of material used, but include tensile strength, high ductility, strength to weight ratio, impact and heat resistance, longevity and hardness. Each of these should be considered with regard for the intended use of stainless steel as should thickness, gauge thickness, overall width and overall length.

Like all stainless steel products, plates begin either as recycled or raw materials which must be heated or melted to their re-crystallization temperature, allowing the mixture to homogenize while burning out any unwanted impurities. Though the specifics vary among the dozens of grades of stainless steel, each is composed primarily of iron ore with at least 10% chromium.

The high concentration of chromium is what gives stainless steel its name and several of its most advantageous qualities. The alloyed chromium forms a "passivation" layer of chromium oxide on the surface of the stainless steel plate or other stainless product. This protective layer is what prevents staining, wear and corrosion. Smaller amounts of carbon, nickel, molybdenum, silicone and aluminum are present in various combinations.

Once thoroughly heated the material is rolled into sheets. Layers are compressed and forged into a single piece that has the desired dimensions. An alternative to this hot rolling process, steel plates may be made through cold rolling which instead forces cooled stainless steel ingots through progressively thinner rollers until the desired thickness is achieved.

Steel service centers will often perform secondary processes such as sawing, heat treating, stress relieving, annealing, normalizing, cutting, testing, milling, deburring, straightening and more to deliver sheets as close to the end product as possible.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services