Stainless steel, also known as chromium steel or corrosion-resistant steel, is a steel alloy made up of at least 10.5% chromium. The percentage of chromium in regular carbon steel is much lower. Its other main elements include: carbon, nickel, molybdenum, copper, manganese, titanium, nitrogen, silicon and Sulphur. Read More…

We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

We are Liberty Specialty Metals, and we specialize in supplying high-performance stainless steel solutions for demanding industrial and commercial applications. Our focus is on delivering premium stainless steel materials that meet exacting standards for strength, corrosion resistance, and long-term reliability.

At Millennium Metals, LLC, we specialize in providing high-quality stainless steel products to meet the diverse needs of our customers across a wide range of industries. We take pride in offering an extensive inventory of stainless steel grades, shapes, and sizes, ensuring our clients have access to the materials they need, exactly when they need them.

At Alliant Metals, we dedicate ourselves to supplying high-quality stainless steel products and tailored services that meet the demands of a wide range of industries. As specialists in stainless steel, we work closely with our customers to deliver material that aligns with their exact specifications, whether the need is for standard stock or custom-cut solutions.

Comprehensive Guide to Stainless Steel: Properties, Applications, and Choosing the Right Manufacturer

More Stainless Steel Manufacturers

Stainless steel—also known as chromium steel or corrosion-resistant steel—is a high-performance alloy engineered for superior durability, strength, and resistance to rust and corrosion. Composed primarily of iron and a minimum of 10.5% chromium, stainless steel often contains additional elements such as nickel, molybdenum, carbon, manganese, copper, titanium, nitrogen, silicon, and sulfur. This complex formulation distinguishes it from standard carbon steel, which lacks the chromium content necessary for robust corrosion resistance.

Stainless steel’s reputation for exceptional mechanical properties and surface durability is well-earned: it is scratch-resistant, resists oxidation, and maintains its luster even in harsh environments. Its ability to withstand high temperatures, combined with ease of cleaning and sterilization, makes it indispensable in both industrial and consumer applications.

While basic steel alloys are derived from iron and carbon (with up to 2.1% carbon), stainless steel’s defining trait is its carefully balanced alloying elements, which not only increase corrosion resistance but also enhance tensile strength, ductility, and workability. Modern stainless steel belongs to a family of over 200 alloys, each tailored for specific industry needs and operating conditions, with carbon content ranging from 0.03% to 1.2%.

Industries and Applications of Stainless Steel

Stainless steel is a cornerstone of modern industry, with global demand increasing at a steady rate of 5% annually. Its unique blend of properties and stainless steel alloys make it a top choice for applications requiring durability, hygiene, and aesthetic appeal. Thanks to its high recyclability—much of it derived from scrap steel—it is also considered an environmentally responsible material, contributing to sustainable manufacturing practices.

Key industries using stainless steel include:

- Food and Catering: Stainless steel’s non-reactive surface makes it ideal for commercial kitchens, food processing equipment, brewing tanks, and utensils, where hygiene and corrosion resistance are paramount.

- Medical Equipment: Surgical instruments, implants, and hospital fixtures rely on stainless steel’s biocompatibility and ease of sterilization.

- Home Appliances: From refrigerators and dishwashers to sinks and cookware, stainless steel provides long-lasting performance and modern aesthetics.

- Chemicals and Pharmaceuticals: Resistant to acids and bases, stainless steel is used in tanks, pipes, and reactors where chemical exposure is frequent.

- Offshore and Shipbuilding: Its ability to withstand saltwater corrosion makes stainless steel vital for marine structures, oil rigs, and vessel components.

- Automotive Manufacturing: Exhaust systems, trim, and structural components benefit from stainless steel’s strength and corrosion resistance.

- Energy and Industrial Sectors: Used in power plants, pipelines, and heavy machinery for its durability and resistance to extreme conditions.

- Architecture and Construction: Cladding, structural supports, and decorative finishes feature stainless steel for its longevity and low maintenance.

Are you looking for specific stainless steel applications tailored to your industry or product needs? Explore our directory of manufacturers or contact a specialist to discuss custom solutions and engineering support.

How Does Stainless Steel Resist Corrosion?

The secret to stainless steel’s remarkable corrosion resistance lies in its protective chromium oxide passivation layer. This ultra-thin layer, formed when chromium in the alloy reacts with oxygen, acts as a shield against oxidation—even if scratched or damaged, it rapidly self-heals. This property is critical for applications where hygiene, longevity, and reliability matter most, such as in food processing, cleanrooms, and outdoor architectural features.

Common Products and Everyday Uses of Stainless Steel

From the intricate gears in medical devices to the gleaming panels of skyscrapers, stainless steel is omnipresent. Its adaptability allows it to be shaped, welded, and finished into a multitude of products, including:

- Elevator doors and frames

- Gutters and roofing components

- Tableware and flatware

- Kitchen sinks and countertops

- Medical and dental tools

- Automotive trim and exhaust systems

- Large storage tanks and chemical processing vessels

Considering a new stainless steel project? Request a quote or compare stainless steel grades to ensure your product meets performance and regulatory requirements.

History of Stainless Steel: The Path to Modern Engineering

The story of stainless steel began in the early 19th century, with the first observations by Pierre Berthier in 1821. Berthier discovered that iron alloyed with chromium resisted corrosion, envisioning its potential for cutlery and kitchenware. However, early attempts at manufacturing resulted in brittle alloys, limiting commercial use.

Progress accelerated in 1872 when British innovators Clark and Woods developed a more durable stainless alloy. Hans Goldschmidt’s invention of the thermite process in the late 19th century enabled carbon-free chromium production, paving the way for improved stainless steel quality. By the early 20th century, researchers like Leon Guillet were fine-tuning alloy compositions and developing the first true stainless steels.

Notable milestones include the first stainless steel yacht built by Friedrich Krupp Germaniawerft in 1908, and Harry Brearley’s accidental discovery of martensitic stainless steel in 1912, while seeking rust-resistant alloys for firearms. Brearley later partnered with American engineer Elwood Haynes to form the American Stainless Steel Corporation, spurring widespread adoption in the United States.

By 1929, the U.S. was producing over 25,000 tons annually, with stainless steel soon becoming essential for military hardware and heavy machinery during World War II. Today, ongoing advancements in stainless steel manufacturing focus on sustainability, cost reduction, and expanding its range of applications.

Properties of Stainless Steel: Why Choose This Alloy?

Stainless steel’s unique blend of physical and chemical properties underpins its global appeal:

- High Strength-to-Weight Ratio: Stainless steel delivers robust mechanical strength, supporting heavy loads and resisting deformation.

- Corrosion and Oxidation Resistance: The chromium oxide layer protects against rust, making stainless steel ideal for challenging environments.

- Temperature Stability: Performs reliably at both elevated and cryogenic temperatures without losing integrity.

- Exceptional Ductility: Stainless steel can be formed, drawn, and fabricated into complex shapes without cracking.

- Low Electrical Conductivity: Useful in applications where electrical insulation is required.

- Biological Inertness: Safe for contact with food, pharmaceuticals, and biological tissues.

- Resistance to Chemicals: Withstands acids, bases, and organic compounds, making it suitable for chemical processing.

- Ease of Cleaning: Non-porous surface resists bacteria and is simple to sterilize.

- Recyclability: Contributes to sustainable manufacturing by being easily recyclable and reusable.

Curious about which stainless steel property is most important for your project? Ask our experts or compare grades by application for tailored recommendations.

How is Stainless Steel Made? Understanding the Production Process

The stainless steel manufacturing process is a multi-stage operation designed to produce a wide variety of forms and products with precise chemical and mechanical characteristics. Here’s how stainless steel is typically fabricated:

- Melting: Raw materials (iron ore, chromium, nickel, etc.) are melted together in an electric arc furnace, typically for 8-12 hours, achieving a homogeneous alloy.

- Casting: The molten metal is cast into shapes such as slabs, rods, blooms, billets, or tube rounds, depending on the intended application.

- Hot Rolling: These cast forms are hot-rolled to reduce thickness and shape the product into sheets, plates, strips, bars, or wire.

- Heat Treatment and Air Hardening: The steel is heat-treated and air-cooled to achieve specific hardness and mechanical properties, tailored by adjusting temperature and cooling time.

- Cleaning: Surface impurities are removed using electro-cleaning, pickling, or other techniques to ensure a clean, corrosion-resistant finish.

- Cutting: Final shapes and dimensions are achieved through precision cutting, using shears, lasers, or water jets.

- Secondary Processing: Further refinement, such as cold rolling, annealing, or surface finishing, provides the desired surface appearance—matte or polished—and final mechanical properties.

Each step in the production process is closely monitored to ensure consistent quality control and adherence to industry-specific standards.

Stainless Steel Grades and Their Industrial Uses

There are more than 150 recognized stainless steel grades, each engineered for particular environments and applications. These grades can be grouped into four primary categories, reflecting their mechanical properties and corrosion resistance:

- 200 Series: Featuring manganese, chromium, and nickel, these non-magnetic alloys are valued for their resistance to pitting and intergranular corrosion. Common in kitchenware, appliances, and automotive trim.

- 300 Series: The most widely used group, especially Grade 304 (18-8 stainless steel)—containing 18-20% chromium and 8-10.5% nickel. This grade offers excellent corrosion resistance in mild atmospheres and freshwater environments, making it a standard for food processing, electronics, and medical instruments. Grade 316, with added molybdenum, provides superior resistance to chlorides—ideal for marine and chemical applications.

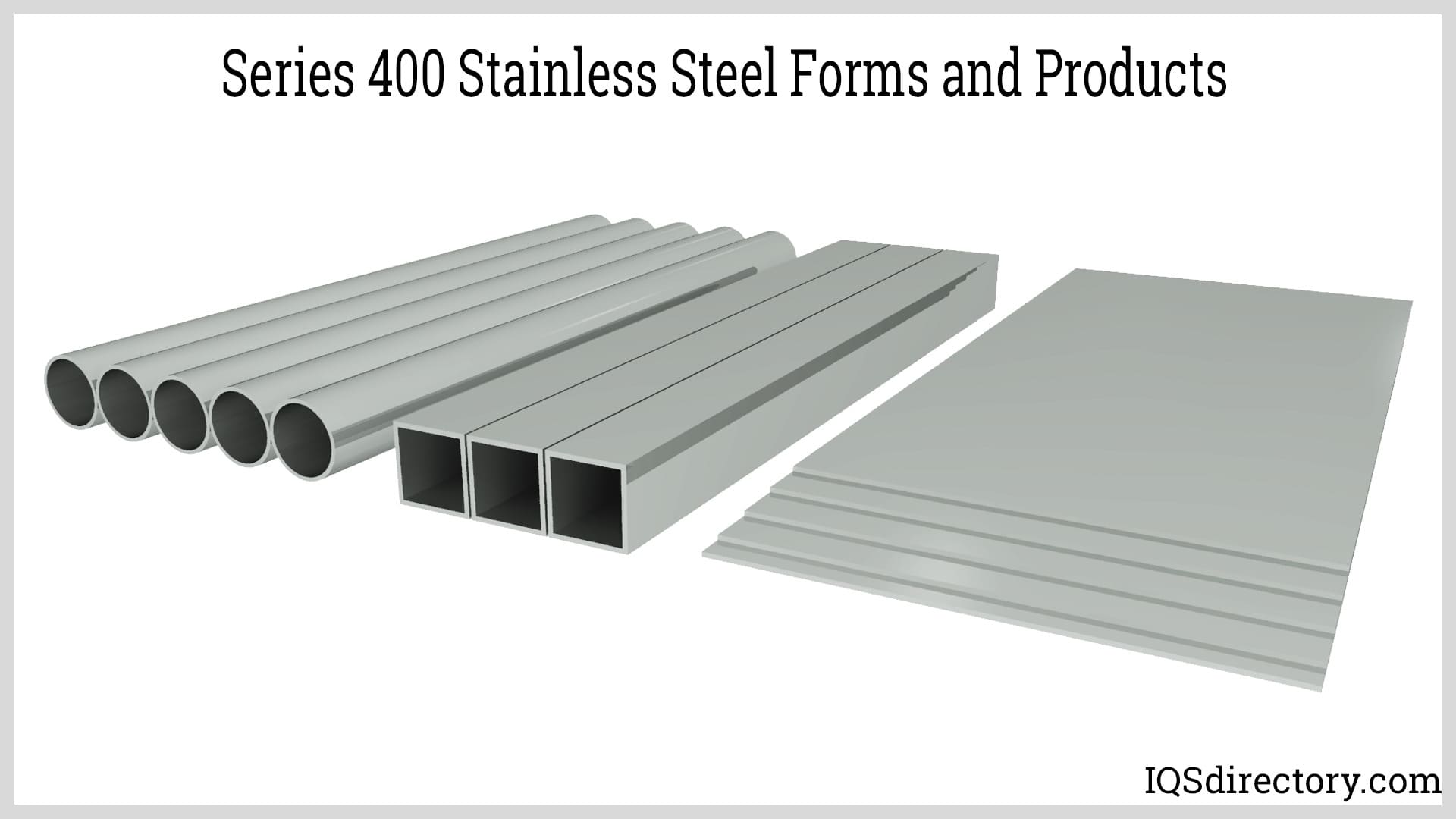

- 400 Series: High in chromium and low in nickel, these alloys (e.g., Grade 430) are magnetic, less expensive, and offer moderate corrosion resistance. They’re often used in automotive components, industrial roofing, and kitchen appliances.

- 600 Series: Known as precipitation hardening stainless steels, these grades (e.g., 17-4 PH) can be heat-treated for exceptional strength and resistance to chloride environments. Common in aerospace, defense, and high-performance engineering.

Not sure which stainless steel grade matches your project? Use our stainless steel grade selector tool or consult our materials engineer for expert guidance.

In-Depth Overview of Key Grades

- Grade 304 Stainless Steel: The industry’s workhorse, used in kitchen equipment, chemical containers, architectural cladding, and more. Non-magnetic in annealed condition, it’s prized for its weldability and hygiene properties.

- Grade 310 Stainless Steel: Recognized for high-temperature strength and oxidation resistance, making it suitable for furnace parts, petrochemical processing, and cryogenic applications.

- Grade 316 Stainless Steel: Enhanced with molybdenum, offering top-tier resistance to salt and chlorinated environments. Often specified for marine, pharmaceutical, and medical equipment.

- Grade 430 Stainless Steel: Cost-effective and formable, used in interior architectural features, dishwasher linings, and automotive trims.

Types of Stainless Steel: Austenitic, Ferritic, Martensitic, and Duplex

Stainless steel alloys are classified by their internal microstructure, which determines their performance and suitability for specific applications:

Austenitic Stainless Steel:

Comprising approximately 70% of stainless steel production, austenitic grades feature high nickel and chromium content, with low carbon. These alloys (primarily 200 and 300 series) are non-magnetic, highly ductile, and offer the best corrosion resistance and weldability. They are the preferred choice for food processing, chemical equipment, and cryogenic applications. The popular 18/10 grade is a prime example, valued for its robustness in both domestic and industrial settings.

Ferritic Stainless Steel:

Containing 10.5% to 25% chromium and little to no nickel, ferritic stainless steels are magnetic and offer good corrosion resistance at a lower cost. These grades are commonly used in automotive exhaust systems, industrial roofing, and appliances where moderate corrosion resistance is needed.

Martensitic Stainless Steel:

With higher carbon and molybdenum content, martensitic stainless steels are hardenable by heat treatment, providing high strength and wear resistance at the expense of some corrosion resistance. Typical applications include cutlery, surgical instruments, and mechanical parts demanding a rugged, rust-resistant finish.

Duplex Stainless Steel:

Duplex grades are a hybrid of austenitic and ferritic structures, offering enhanced strength, superior resistance to stress corrosion cracking, and excellent performance in aggressive environments. Used in pressure vessels, chemical tanks, and marine components where both strength and corrosion resistance are essential.

Wondering which stainless steel type is right for your project? Compare austenitic, ferritic, martensitic, and duplex stainless steels based on your specific requirements.

Stainless Steel Products: Forms and Custom Fabrication

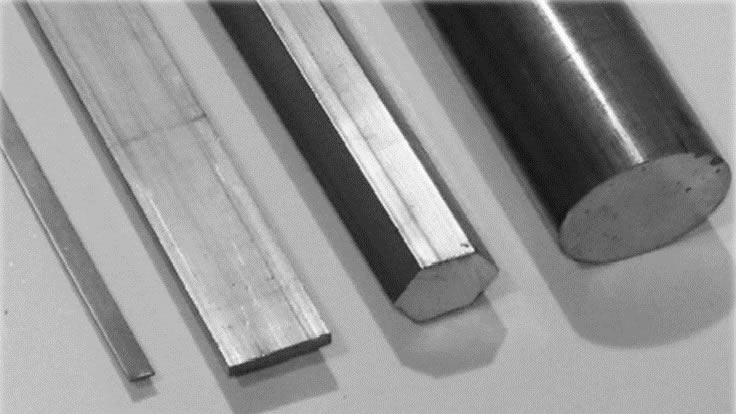

At a modern steel service center, you’ll find an extensive array of stainless steel products and forms, available to suit any manufacturing or fabrication need. Leading stainless steel suppliers stock:

- Bars – round, square, hexagonal, and custom profiles

- Sheets – various thicknesses and finishes

- Plates and coils for heavy-duty construction and industrial applications

- Tubes, seamless and welded pipes, for plumbing, HVAC, and oil & gas sectors

- Wire, strip, and foil, for electronics, medical devices, and specialized equipment

- Rods for structural and machining applications

These raw materials are fabricated into finished products such as:

- Kitchen and restaurant equipment

- Industrial tanks and silos

- Automotive and aerospace parts

- Architectural panels and handrails

- Medical and pharmaceutical devices

- Laundry and sanitation equipment

Need custom stainless steel fabrication? Request a quote for your next project or compare supplier capabilities and turnaround times.

Top Benefits of Stainless Steel: Why It’s the Material of Choice

Stainless steel stands out for its unparalleled combination of benefits, making it the preferred choice for manufacturers, builders, and engineers:

- Eco-Friendly and Sustainable: Fully recyclable, reducing environmental impact and supporting green construction initiatives.

- Versatile and Customizable: Available in over 150 standard grades, with the ability to engineer custom alloys to meet unique needs.

- Low Maintenance and Durable: Requires minimal upkeep, resists wear and tear, and outperforms lesser metals that might corrode or degrade over time.

- No Need for Protective Coatings: Unlike carbon steel, stainless steel does not require painting or special surface treatments for corrosion resistance.

- Aesthetic Appeal: Offers a sleek, modern look that enhances architectural and consumer products.

- Cost-Effective Over Lifecycle: Higher initial investment is offset by reduced maintenance and replacement costs.

Still weighing your material options? Compare stainless steel with aluminum, carbon steel, or other alloys to assess total cost of ownership.

Why is High-Quality Stainless Steel Critical?

Using premium-grade stainless steel ensures reliable performance, safety, and longevity across all applications—be it consumer goods, critical infrastructure, or industrial equipment. High-quality steel offers:

- Consistent Material Properties: Ensures predictable performance in engineering, machining, and assembly.

- Superior Durability: Withstands rigorous mechanical stress and environmental challenges.

- Precision Manufacturing: Facilitates tight tolerances and intricate designs, meeting exacting specifications.

In contrast, lower-grade or improperly processed steel is prone to failure, increasing risk and potentially incurring costly downtime or product recalls. To guarantee quality, manufacturers conduct comprehensive testing for:

- Homogeneity

- Workability

- Hardening and tempering

- Corrosion resistance

- Elasticity and mechanical strength

Looking for certified, high-quality stainless steel suppliers? Browse our curated manufacturer listings or download our quality assurance checklist for your procurement process.

How to Choose the Right Stainless Steel Manufacturer

Selecting the best stainless steel contract manufacturer is essential for project success. Consider these key factors:

- Does the manufacturer offer the precise services you need (e.g., custom fabrication, finishing, rapid prototyping)?

- Can they meet your technical specifications and stringent quality standards?

- Are their products competitively priced to fit your budget constraints?

- Do they have the capacity to deliver within your project timeline?

- Do they hold relevant ISO certifications or equivalent quality management credentials?

- Are their processes compliant with ASTM, ASME, or other industry safety and quality standards?

- Do they provide expertise in custom or complex manufacturing requirements?

Tip: Always review case studies, client testimonials, and supplier accreditations to verify reliability and past performance. Contact manufacturers directly from our directory for detailed quotes and consultation.

What are the ISO Standards for Stainless Steel?

ISO standards—set by the International Organization for Standardization—are crucial benchmarks in the stainless steel industry, ensuring product quality, safety, and consistency worldwide. ISO certification confirms that a manufacturer’s processes comply with strict international criteria.

For stainless steel and other metal materials (Group “P”), ISO standards cover:

- Technical specifications and chemical composition

- General characteristics and supply conditions

- Testing and quality control methodologies

- Traceability and product documentation

Key standards include:

- ISO 9001:2015 – Quality management systems

- ISO 377 – Sampling methods for mechanical testing

- ISO 404 – Technical delivery requirements

- ISO 10474 – Inspection documentation

- ISO 4948-1 and ISO 6929 – Classification and terminology for steels

Want to ensure your stainless steel products meet global standards? Download our ISO compliance checklist or contact certified manufacturers for documentation and certifications.

The Global Stainless Steel Market: Sourcing and Supply Chain Insights

The stainless steel market is a dynamic, interconnected global industry, with production and trade spanning the United States, Europe, Asia, and beyond. U.S.-based steel service centers not only serve domestic infrastructure, manufacturing, and construction, but also export to international markets. Conversely, many American businesses import specialty stainless steel from overseas suppliers to access unique grades or cost efficiencies.

As of 2015, North America ranked third in global steel production, behind Asia (led by China) and the European Union. International competition has influenced domestic pricing and availability, prompting buyers to carefully assess sourcing strategies.

While importing stainless steel can offer cost advantages, buyers should consider:

- Communication Barriers: Time zone differences, language issues, and cultural nuances can complicate orders and troubleshooting.

- Lead Times and Logistics: Shipping delays and customs clearance may extend project timelines.

- Quality Assurance: U.S. suppliers are subject to rigorous domestic safety and quality standards, ensuring higher confidence in specification compliance.

- After-Sales Support: Domestic suppliers typically provide faster resolution for warranty or quality issues.

Need help choosing between domestic and international stainless steel sources? Compare supplier performance, review trade regulations, or consult with a supply chain expert to make informed decisions.

Frequently Asked Questions About Stainless Steel

- What’s the difference between stainless steel and regular steel? Stainless steel contains at least 10.5% chromium, which forms a protective oxide layer and prevents rust, unlike standard carbon steel.

- How do I select the right stainless steel grade for my project? Consider the environment (corrosive, high-temperature, food-safe), mechanical strength needs, and fabrication requirements. Contact our technical support for a personalized recommendation.

- Is stainless steel safe for food and medical use? Yes, food-grade and medical-grade stainless steels are biologically inert, easy to sterilize, and compliant with strict hygiene regulations.

- Can stainless steel be recycled? Absolutely. Stainless steel is 100% recyclable without loss of quality, supporting green building and sustainable manufacturing.

Take the Next Step: Connect with Leading Stainless Steel Manufacturers

Ready to source high-quality stainless steel for your next project? Browse our curated directory of stainless steel manufacturers to compare capabilities, certifications, and product offerings. Whether you need standard grades, custom alloys, or specialized fabrication, our network connects you with trusted suppliers who deliver performance, reliability, and value.

Still have questions? Request a consultation, download detailed product guides, or submit your technical requirements for expert recommendations tailored to your needs.

Discover why stainless steel is the material of choice for industries that demand the best in strength, durability, and sustainability—partner with a proven supplier today!

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services