We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Rod Manufacturers

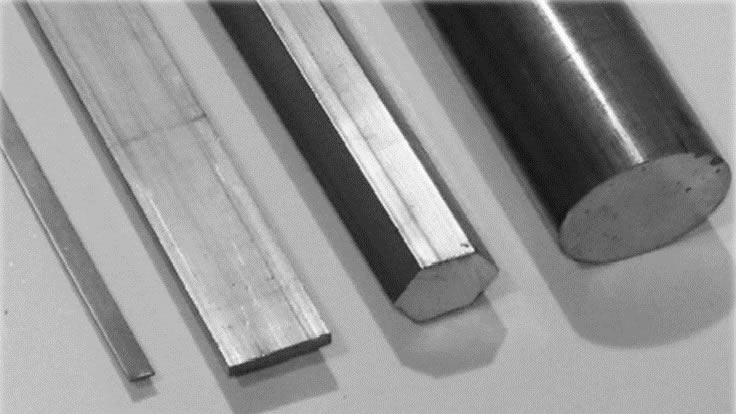

Though the name rod is sometimes used interchangeably with stainless steel bars, rods most often have a circular cross-section whereas bars can be produced in squares, hexagons, octagons or flats.

How Stainless Steel Rods are made.

Step 1: Melting.

Scrap metals and additives are first melted in an electric arc furnace to create stainless steel (EAF). The EAF heats the metals for many hours using high-power electrodes to create a molten, fluid mixture. Since stainless steel is recyclable, many orders for the material comprise up to 60% recycled steel. This helps to lessen the impact on the environment and the expense. Different temperatures will be needed depending on the type of steel produced.

Step 2: Carbon Content Removal.

With the assistance of carbon, iron gets stronger and harder. However, too much carbon might cause problems, including carbide precipitation while welding. Therefore, before casting, it is essential to calibrate and lower the carbon content of molten stainless steel to the proper level.

Step 3: Tuning

The decrease of carbon results in the final equilibrium and homogenization of temperature and chemistry. This ensures that the batch's steel composition remains stable and that the metal meets the requirements for its intended grade.

Step 4: Forming or casting

The foundry now has to produce the crude shape that will be used to cool and work the steel once it has been created as molten steel. The finished item will determine the precise form and size.

- Tubes

- Blooms

- Billets

- Slabs

- Rods

The batch is then tracked through the numerous processes that will come after by marking the forms with an identifier. Depending on the targeted grade and final item or function, the following procedures will vary. Plates, strips, and sheets are made from slabs. Blooms and billets transform into wires and bars. Steel may go through several of these processes more than once to provide the required appearance or qualities, depending on the grade or format specified the next steps are the most typical.

Hot Rolling

The batch is then tracked through the numerous processes that will come after by marking the forms with an identifier. Depending on the targeted grade and final item or function, the following procedures will vary. Plates, strips, and sheets are made from slabs. Blooms and billets transform into wires and bars. Steel may go through several of these processes more than once to provide the required appearance or qualities, depending on the grade or format specified the next steps are the most typical.

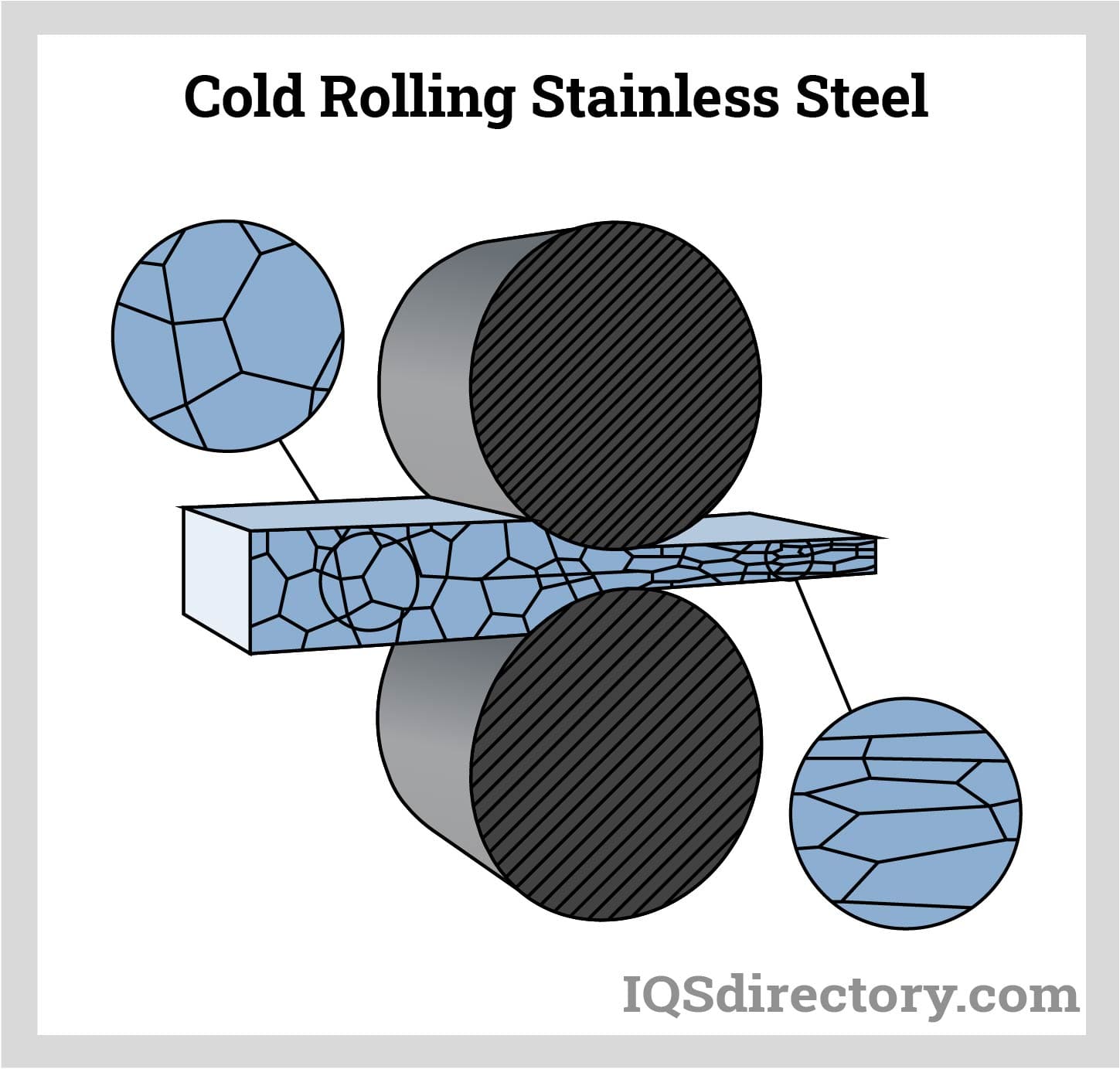

Cold Rolling.

Cold rolling takes place below the temperature at which the steel recrystallizes, and is frequently utilized when precision is needed. The steel is formed using several supporting rollers. This method yields a finish that is more appealing and consistent. It can, however, also deform the structure of the steel, and frequently, heat treatment is necessary to recrystallize the steel to its original microstructure.

Annealing

The majority of steel goes through an annealing process after rolling. Cycles of controlled heating and cooling are involved. These cycles remove internal stress and soften steel. The quality of steel will determine the precise temperatures and duration, with heating and cooling rates having an impact on the finished product. .

Descaling or Pickling

Scale frequently forms on the surface of steel when it is processed through various processes; this accumulation is not merely unsightly. Additionally, it may affect the steel's stain resistance, robustness, and weldability. The oxide barrier that gives stainless its distinctive corrosion and stain resistance must be created by removing this scale. This scale is removed by descaling or pickling, which involves either controlled heating and cooling in an oxygen-free atmosphere or acid baths (referred to as acid pickling). The metal may return to rolling or extruding for additional processing, depending on the ultimate product. Repeated annealing processes are then performed until the desired characteristics are attained.

Cutting

The batch is cut to fit order specifications once the steel has been processed and prepared. Mechanical techniques like cutting with guillotine knives, circular knives, high-speed blades, or pounding with dies are the most popular. However, flame cutting or plasma jet cutting may also be employed for intricate shapes. The optimum choice will depend on the requested steel grade and the final product's desired shape.

Finishing

There are many different finishes for stainless steel, ranging from matte to mirror. Acid or sand etching, sandblasting, belt grinding, belt buffing, and belt polishing are typical methods. Large quantities of stainless steel are frequently shipped and stored in coils and rolls for use in various production procedures. The ultimate form, however, will be determined by the needed steel type and other order-specific elements.

Application of stainless steel rods.

These stainless steel round bars are utilized in the chemical industry because they have the best corrosion resistance characteristics. It is suitable for use in harsh environments that may contain saltwater or other corrosive materials, such as ocean bottoms and structures along the coast. Structures, appliances, and machines are all made with stainless steel round bars. The substance is also used to make jewelry and medical devices. Stainless steel round bars are employed in a variety of industrial processes in addition to the production of cutlery and kitchenware. Round stainless steel bars are used in many industries, including plumbing, construction, and the car industry.

Choosing the Correct Stainless Steel Rod Supplier

To make sure you have the most beneficial outcome when purchasing stainless steel rods from a stainless steel rod supplier, it is important to compare at least 4 to 5 companies using our list of stainless steel rod suppliers. Each stainless steel rod supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel rod company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple stainless steel rod companies with the same quotes.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services