We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Sheet Manufacturers

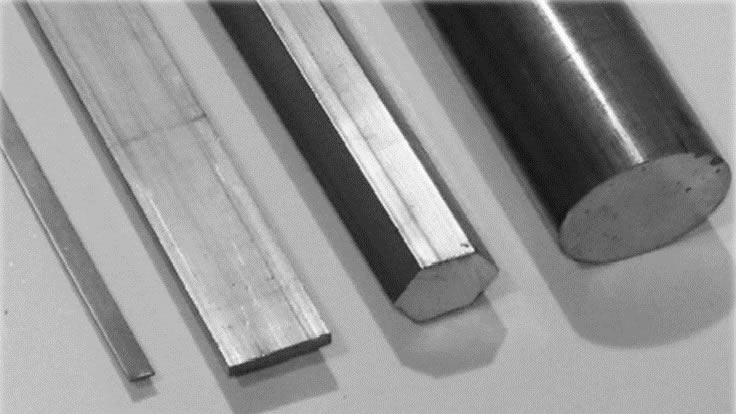

In general, these forms are thicker than stainless steel foil, but thinner than stainless steel plates. Thicknesses between 0.006inches and 0.250inches most commonly constitute a sheet though individual manufacturers may vary.

The thinness of stainless steel sheets is what makes them a popular choice as they are easily formed to specific shapes, but sturdy enough to hold a solid form after processing, which renders them vital to industries such as architecture, automotive, parts manufacturing and more. The material composition also boasts several benefits that make stainless steel sheeting a popular choice in the above industries as well as aeronautics, marine, medical and construction applications.

Stainless steel is not just one particular grade of steel, but a group of steel alloys lauded for extreme resistance to rust, wear and corrosion even in extreme or harsh conditions such as saltwater or chemical processing. Additional characteristics such as high ductility, strength and hardness add to the popularity of stainless steel products. Though the initial cost of stainless steel sheets may be higher than less corrosion resistant alternatives, stainless steel products are recyclable allowing manufacturers to recoup some expenses through scrap value.

The advantageous properties of stainless steel sheets are attributed to the specific composition of each grade of the metal. In general, stainless steel is an alloy of regular steel (iron ore which has been highly refined) and at least 10% chromium, along with much smaller amounts of carbon, nickel, molybdenum, silicone and aluminum in various combinations. The alloyed chromium forms a "passivation" layer of chromium oxide on the surface of the stainless steel sheet.

This protective layer is what prevents staining, wear and corrosion and gives this group of alloys their name. It is important to consider the specific composition of stainless steel sheeting with regards to the intended use of the material as even slight variations can have a significant effect on strength, corrosion resistance and price. Additional considerations include thickness, gauge thickness, overall width and overall length.

The specific method of production should also be considered as stainless steel sheet can be cast, wrought, extruded, compacted, cold finished, drawn or hot rolled with the latter being among the most common. Once purchased for a given application these stock shapes may undergo many different processes such as heat treating, descaling, roll forming, punching, stamping, slitting, cutting, metal spinning and other fabrication methods which create the panels, sinks, encasements, utensils and various other final components.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services