We provide the best products in the stainless steel industry. Our customers know they can trust us for quality, affordability, and convenience. Our multiple locations make it easy to get what you need within days!

Cada Stainless is a distributor of stainless steel in strip, coil & sheet. All grades of stainless steel available- annealed, tempered in 301,302,304,316, straight and L grades, 17/4, 17/7, 420,430,440, temper rolling to specific thicknesses & tolerances available.

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

You can’t beat the EMJ Advantage for stainless steel and other metals, which comes with an "On Time, Or Free" delivery guarantee! For stainless bar, tube, plate and more, including alloy, aluminum, carbon and others, rely on this broad network of superior inventories and capabilities. See our website today to find the sales location nearest you!

At CBC Specialty Metals & Processing, we pride ourselves on being a premier provider of high-quality stainless steel products and comprehensive processing solutions tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted name in stainless steel distribution and processing, renowned for our commitment...

More Stainless Steel Foil Manufacturers

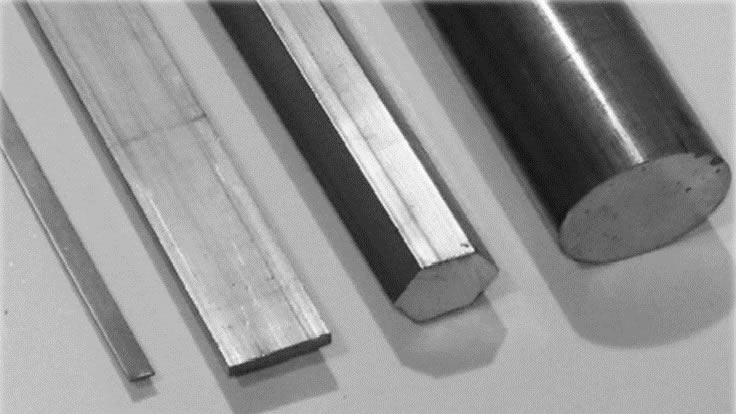

Able to withstand temperatures of up to 2240ºF, stainless steel foil also offers a high strength to weight ratio and resistance to oxidation at high temperatures.

Generally referred to as tool wrap, the most common application of stainless steel foil is to provide increased dimensional stability that helps prevent surface decarburization and other contamination of tool steel parts while they are undergoing heat treatment as well as being cool hardened.

Additional applications of stainless steel foil include shielding for high vacurm applications, x-ray imaging, heating elements and turbine engines. Formed using rolling mills and annealing processed, stainless steel foil can also be used to form stainless steel foil tape, which bonds to most metals and provides advantages such as vapor barrier protection and waterproof sealing.

Common industries that utilize stainless steel foil include manufacturing, medical, automotive, aerospace, defense, petrochemical, laboratory, nuclear and marine. Even though the material is very strong, stainless steel foil can be sheared, perforated or punched in order to better fit the desired application.

Stainless steel foil is typically made from the 200 and 300 series of stainless steel grades, which are all types of austenitic stainless steel. A non-magnetic type of stainless steel, austenitic stainless steel has the highest ratio of chromium and can be used in mild, harsh and corrosive environments. As a result, stainless steel foil is non-magnetic and highly corrosion-resistant.

The most common grades used to make stainless steel foil are 304 and 316. 316 stainless steel is an austenitic alloy that contains 16% chromium, 10% nickel and 2% molybdenum. As a result, 316 stainless steel foil is characterized by its high corrosion resistance as well as having excellent characteristics for forming and welding. 304 stainless steel is the most popular type of austenitic stainless steel and it is comprised of iron, 18-20% chromium and 8-10% nickel.

In addition, 304 stainless steel is easily formed and welded but is not a free-machining material. As a result, 304 stainless steel foil can withstand higher temperatures than aluminum foil as well as being Ultra High Vacuum (UHV) compatible. Additional grades used to form stainless steel foil include 430, 201, 301, 309, 302, 321 and 347.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services